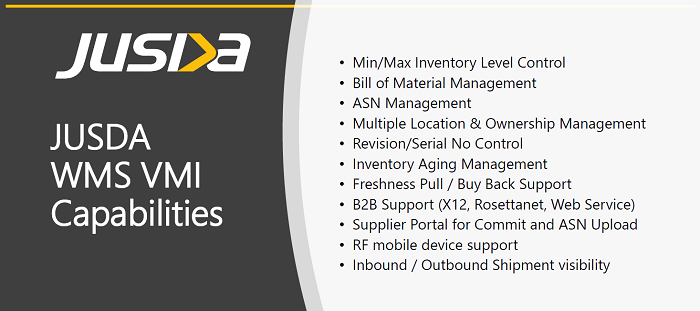

Technology

Vendor Managed Inventory

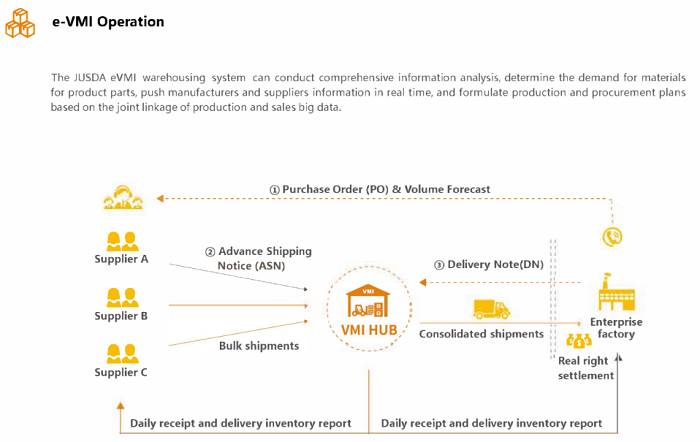

With the radically redesigned and improved JUSDA VMI tool our customers can now take advantage of of the many benefits of our newest online VMI portal.

VMI

Given the disruptive nature of the supply chain dynamics, an important aspect of supply chain planning and control is the attempt by supply chain managers to improve supply chain performance. One way of avoiding this is to allow an upstream supplier to manage the inventories of its downstream customer. This is commonly known as vendor managed inventory (VMI).

Vendor managed inventory (VMI) is a supply chain initiative where the supplier is authorized to manage inventories of agreed-upon stock-keeping units at customer locations. The benefits of VMI Program are well recognized by successful retail businesses such as Wal-Mart.

Definition of Vendor Managed Inventory

Vendor managed inventory (VMI) is defined as inventory which is managed by the supplier / vendor. Vendor Managed Inventory (VMI) involves another party, other than customer, taking responsibility for elements of inventory management, including setting and managing inventory levels, re-ordering, and replenishing.

Some Examples of Vendor managed inventory (VMI) are:

- Vendor at the customer site, Vendor deciding when and how much inventory needs to be ordered, but the actual ordering and owning of the inventory is by customer (example Fastener VMI)

- Vendor at the customer site, vendor in possession of the inventory, making the inventory decisions and placing the orders, with customer taking ownership of the inventory when customer takes the item of inventory for use (ex: Tool Crib/Items issued through supplier owned vending machines).

- Vendor not at the customer site, vendor has inventory at the customer site and periodically reviews (either remotely or physically) the inventory on hand and restocks the inventory when the vendor deems it necessary. A form of consigned inventory.

- Vendor not at the customer site, subcontracts the inventory management to a third party and has the inventory also held in a third party warehouse, from which it is shipped and replenished (example UPS VMI)

In summary Vendor-managed inventory (VMI) is a collaborative strategy between a buyer and supplier to optimize the availability of products at minimal cost. Overall, inventory management cost plays a significant

role in reducing supply chain cost. Specifically in the fast-moving consumer goods (FMCG) sector, inventory–turnover ratio needs to be very high to compete in the global market. Throughout the supply chain, VMI is used to cut inventory-related costs and keep inventory levels low.

VMI helps organizations to reduce the inventory-associated costs by shifting the responsibility of managing and replenishing inventory to vendors.

Typical Vendor Managed Inventory (VMI) Process:

When Customer needs product, they place an order against a supplier. Customer should be in total control of the timing and size of the order being placed, based on one of the examples above. Customer maintains the inventory plan.

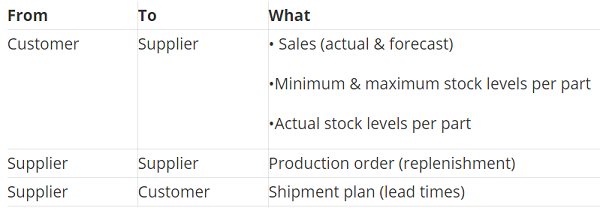

The supplier receives electronic data (usually EDI or via the internet) that tells supplier customer’s sales and stock levels. The supplier can view every item that customer carries as well as true point of sale data in most cases. The supplier is responsible for creating and maintaining the inventory plan. Under VMI, the supplier generates the order for replenishment VMI inventory, not customer. Hence, the term Vendor Manage Inventory!

Important point to note here is VMI does not change the “ownership” of inventory. It remains as it did prior to VMI.

Benefits of Vendor Managed Inventory (VMI)

DUAL BENEFITS for both supplier and Customer:

- Data entry errors are reduced due to computer to computer communications. Speed of the processing is also improved.

- Both parties are interested in giving better service to the end customer. Having the correct item in stock when the end customer needs it, benefits all parties involved.

- A true partnership is formed between the supplier and the customer. They work closer together and strengthen their ties.

- Stabilize the timing of Purchase Orders – PO’s are now generated on a predefined basis.

Customer BENEFITS:

- Better visibility will make it possible to change from Air- to sea freight

- The goal is to have an improvement in Fill Rates from the supplier and to the end customer. Also, a decrease in stockouts and a decrease in inventory levels.

- Planning and ordering cost will decrease due to the responsibility being shifted to the supplier.

- The overall service level is improved by having the right product at the right time.

- The supplier is more focused than ever in providing great service.

Suppliers BENEFITS:

- Visibility to the customers Point of Sale data makes forecasting easier.

- Promotions can be more easily incorporated into the inventory plan.

- A reduction in customer ordering errors (which in the past would probably lead to a return)

- Visibility to Stock Levels helps to identify priorities (replenishing for stock or a stockout?). Before VMI, a supplier has no visibility to the quantity and the products that are ordered. With VMI, the supplier can see the potential need for an item before the item is ordered.

Information Considerations

Risk in Vendor Managed Inventory (VMI)

In our experience following risks needs to be managed in Vendor Managed Inventory (VMI) transaction:

- Slow Moving items: It is not ideal to include slow moving items in VMI model. If the items has stock turn of 4 or less we would not recommend. Generally supplier asks customer to take inventory if not moved in 4 months max.

- Physical Count of Inventory: suppliers and customer must make sure the ownership of physical stock count is defined from the outset of agreement.

- New Product Introduction/Phase Out Items: We have found it is headache to manage to manage New Production Introduction and Phase Out plans for inventory on ramp down. This scenario needs special communication.

- Monthly Exception: We all trust the data in the system, don’t we!! On serious note we like to trust data in our ERP or Inventory management system, but discrepancies are bound to occur over long period of time. Therefore, we strongly recommend to monthly exception reporting to align physical inventory between supplier and customer.

Conclusion

Vendor-managed inventory (VMI) is a collaborative strategy between a buyer and supplier to optimize the availability of products at minimal cost. Overall, inventory management cost plays a significant role in reducing supply chain cost.

VMI is a logistics distribution strategy through which the supplier manages inventory at customers’ sites and decides on replenishment policies, subject to stipulated levels of availability and service. The supplier benefits by reducing its inventory levels, reducing customers’ demand variability, and improving routing strategies; customers benefit by reducing resources dedicated to manage inventories and by decreasing their stock-outs, thus increasing their revenues

VMI is made possible by installing technological equipment at participating sites to allow the supplier to keep track of customer demand and inventory. The decrease in the cost of applicable technologies, such as EDI and the Internet, has accelerated the adoption of this strategy across several industries. The objective of the supplier in VMI is to decide on distribution tactics that will minimize the inventory and transportation costs across the supply chain.

Whilst there are many benefits of Vendor-managed inventory (VMI) , there are few risk as well, which needs to be considered.

Make sure to connect with us to get a VMI product demo today! Download sales sheet.