Supply Chains

Tips for Supply Chain Logistics & Storage

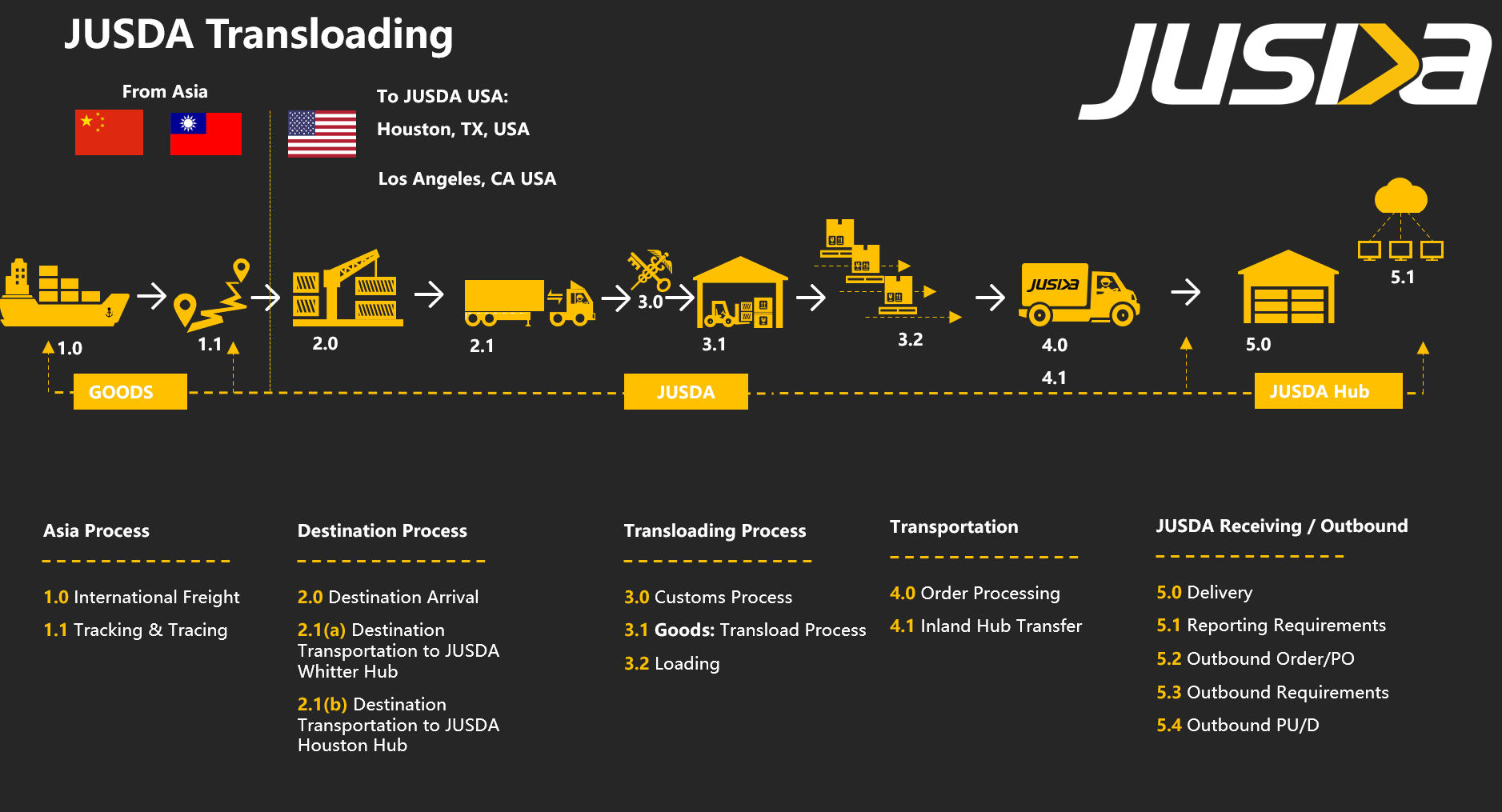

Logistics is always present in supply chain. But as each company has its own particularities, it is necessary to apply the supply chain storage operations according to the project profile.

1 – Understand the activities involved in the storage process

Product supply chains that work with a high volume of goods of different natures are tricky. The size of the warehouse will depend on the flow of products and people and the size of the supply chain itself.

In any case, a warehouse manager must be aware of the main activities related to the storage process:

- Receiving

- Inspection

- Addressing

- Stocking

- Separation

- Packing

- Loading

- Expedition

- Documents & inventories issuance

2 – Adjust the storage systems to the facility profile

A good storage system helps the supervisor to perform effective management. Voice picking systems, for example, allow it to record messages every day on a radio type, and employees receive such communications through a headset. Most of the supply chains that adopted this system were satisfied with the results obtained at the end of a given period.

The storage systems can be adjusted to the supply chain profile, satisfying your needs. Milk cartons, for example, are very perishable products in supermarkets, and a stacking with a maximum number of boxes is recommended. Thus, a shelf can be designed to contain only the allowable amount.

In addition to shelving and racking, supply chains generally rely on systems such as cantilevers and pallet trucks. All are efficient, and it is up to the manager to choose those that best fit his reality.

3 – Set a strategic position on the shelves

During storage, in addition to the care related to the fragility of each product when placing them on the shelves (lighter and smaller products are at the top), it is also necessary to consider the strategic positioning on the shelves. This means that those products that sell a lot must be located in the stock in places of easy access to the repository.

A wrap up: products with high demand should be allocated in locations that are easily accessible to the repository; items with low demand can be put in places without so much accessibility.

4 – Make efficient inventory control

Adequate inventory control should consider a few points, such as the optimal use of space in three dimensions, ie width, height and length. All installations must allow a fast product movement in any direction, from receipt to dispatch.

Efficient inventory control will take into account all the activities performed in storage, by striving to be carried out with agility and offer the best results. These activities should be well integrated with each other and the responsible(s) for coordinating them should have knowledge on the subject and a lot of responsibility.

Logistics in supply chains generally have high costs, but it is fundamental to ensure good service and the supply of good quality products.

5 – Bet on the use of technology

To help reduce logistics costs, a good alternative is to purchase logistics software for inventory management. In addition to lowering costs, it increases the efficiency of operations. Computerizing inventory management is one way of integrating this industry into other areas, such as the purchasing department and the cashier. It is possible to issue reports that identify errors by using technology and making it easier to correct them and improve the work.

Electronic cataloging, for example, favors the quick location of a particular item and its transfer to the place of sale. In many supply chains, they already use robots, metal carousels and different digital resources to improve efficiency.