Manufacturing

Nearshoring to Mexico

"Nearshoring" is the transfer of business processes to companies in a nearby country, where both parties expect to benefit from one or more of the following dimensions of proximity: geographic, temporal (time zone), cultural, linguistic, economic, political, or historical linkages. Nearshoring is a derivative of the business term "offshoring". In contrast, nearshoring means that the business has shifted work to a lower cost organization, but within its own region, broadly defined.

After the rapid spread of COVID-19, China went into extreme lockdown and factory production declined or was halted. Shipping of goods were also stopped or drastically curtailed. One example of this was the production of the N95 masks needed worldwide as personal protective equipment; these were not coming out of China, which exacerbated a critical shortage. This supply chain reliance on China highlights a weakness for many U.S. and global organizations. For some companies, a disruption like COVID-19 can mean a stop to all their product flow. Alternatively, businesses that produce in multiple countries have the strategic advantage to shift their production to other manufacturing bases; this has been a strategy employed by many firms trying to stay competitive in turbulent times.

As the Coronavirus has spread globally, no country is immune from the production and shipping disruptions it has created, not even Mexico. While the pandemic has not benefited or hurt only one country, its main lesson has been that the resilience of a firm’s supply chain is of key importance.

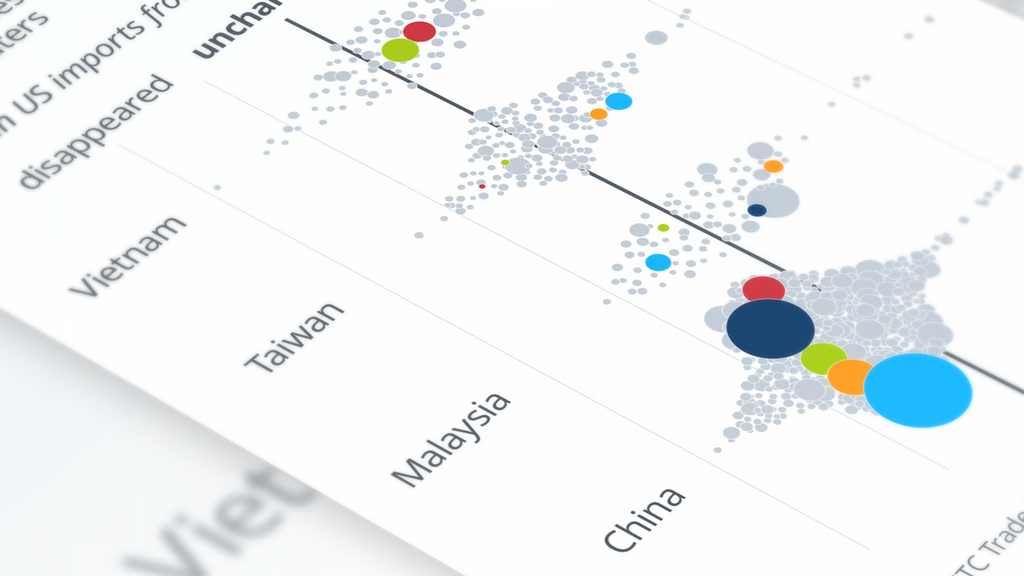

For many it is not a question of eliminating Chinese production, but rather, diversifying the supply chain to eliminate having all of one’s eggs in one basket. While Mexico is not the only option to China, it offers proximity to U.S. markets, a young workforce at competitive salaries, low/no tariffs and protection of intellectual property. This makes it one of the top contenders as a manufacturing option. Even Chinese companies are now choosing to manufacture outside China – often in Mexico – to speed up the supply chain into the U.S. and avoid tariffs. No matter how they each achieve it, companies today need to protect their own businesses by analyzing all the options and creating a robust and flexible supply chain.

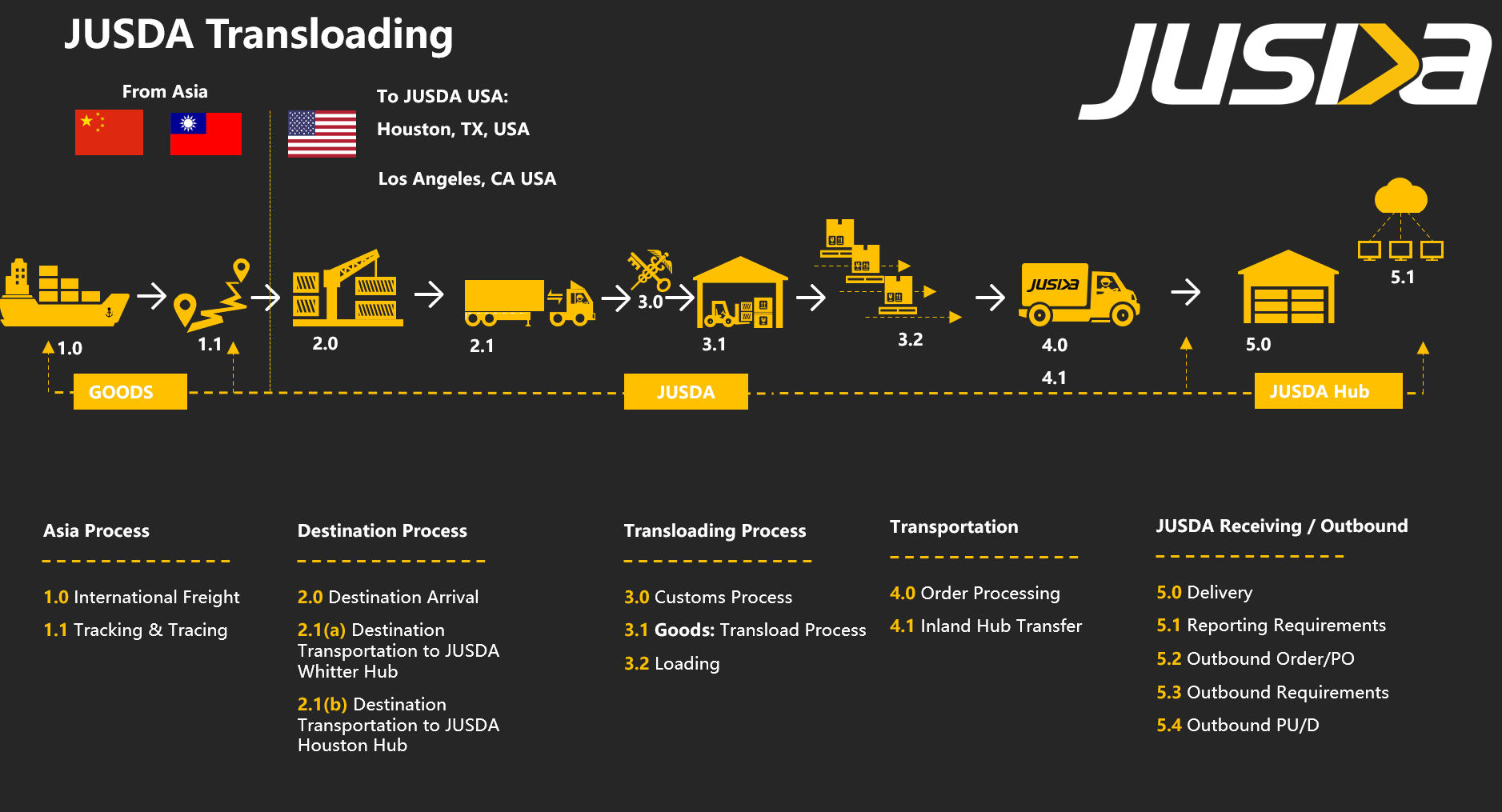

For JUSDA, this means assisting our customers with the complicated logistical, supply chain and regulatory challenges of moving parts into Mexico and produced goods out of Mexico and into the United States. Let us know if you would like to find out more about how we can help!